CNC machining delivers the precision that modern manufacturing demands. However, producing reliable components requires a straightforward, repeatable workflow. Each step reduces risk and improves consistency. Therefore, factories follow a sequence from design to delivery. Below, we walk through the practical steps needed to produce high-quality CNC machining parts. We cover design, material choice, programming, setup, machining, inspection, finishing, and shipping. Moreover, we explain why each stage matters and how it links to the next.

Design and CAD modeling

First, engineers create a CAD model. The model defines geometry, tolerances, and surface finish. Then, designers perform a manufacturability review. They check for thin walls, deep pockets, and undercuts. Next, they add critical dimensions and notes for machining. Importantly, early design for manufacturability saves time and money later. Therefore, good CAD work simplifies CAM programming and reduces errors. In short, the design stage sets the foundation for all downstream work in a CNC machining part.

Material selection and blank preparation

After design, choose the right material. Common choices include aluminum, stainless steel, titanium, and engineering plastics. Material affects strength, weight, and machinability. Moreover, suppliers must provide stable, defect-free stock. Then, technicians cut raw material into blanks sized for the machine. They also inspect for impurities and internal defects. Proper blank preparation prevents vibration and part shift during cutting. Thus, careful material selection and prep directly support dimensional accuracy in CNC machining parts.

CAM programming and toolpath optimization

Next, CAM software converts CAD into G-code. Programmers generate efficient toolpaths and sequence operations. They select speeds, feeds, and tool changes. Then, they simulate the program to catch collisions and errors. Significantly, optimized toolpaths reduce cycle time and tool wear. Also, programmers include coolant strategies and lead-in paths. Consequently, solid CAM work improves quality while lowering cost. In short, careful programming forms the engine that drives accurate CNC machining parts.

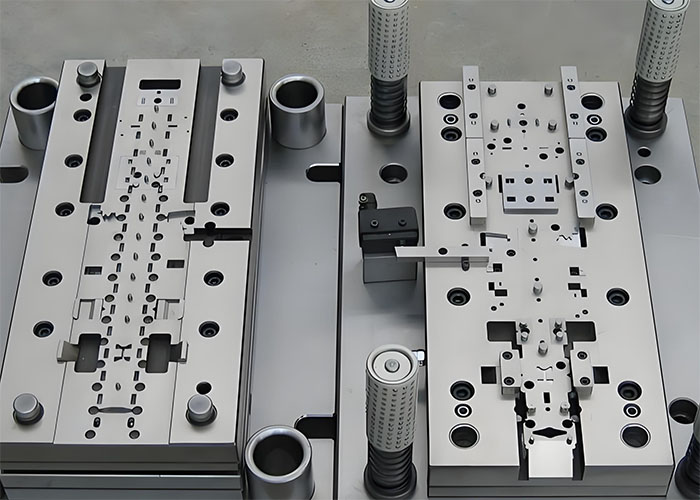

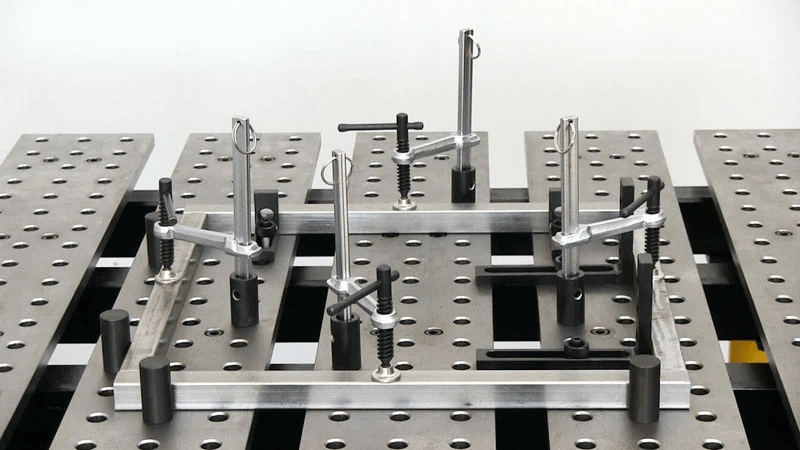

Machine setup, tooling, and fixturing

Before cutting, technicians prepare the machine. They install tooling, set offsets, and mount fixtures. Accurate fixturing holds the part firmly and repeats locations across runs. Additionally, they check spindle runout and tool balance. Then, they load the program and run dry cycles if needed. Setup verification ensures the physical setup matches the digital plan. Therefore, a precise setup minimizes rework and scrap. Ultimately, good fixturing and tooling underpin repeatable CNC machining parts.

Machining operations and in-process control

With setup complete, the machine executes the program. Operations include milling, turning, drilling, and tapping. Operators monitor tool wear, chip formation, and machine loads. Moreover, they measure key features during the run when necessary. If a tool shows wear, they change it and adjust offsets. Real-time checks prevent costly failures. In automated cells, sensors can halt the process on anomalies. Hence, active in-process control maintains tolerance and surface finish, which leads to reliable CNC machining parts.

Inspection, metrology, and quality assurance

No parts ship without inspection. Technicians use calipers, micrometers, and CMMs to verify dimensions and geometric tolerances. They also check surface finish and concentricity. First-article inspection validates the setup before complete production runs. Then, statistical process control tracks variation across batches. Nonconformances trigger root-cause analysis and corrective actions. Additionally, traceable records support customer audits and certifications. In effect, rigorous QA systems ensure each batch of CNC machining parts meets the required standard.

Post-processing, finishing, and assembly

After machining, parts often need secondary work. Typical steps include deburring, shot peening, heat treatment, anodizing, and coating. Some parts require precision grinding or honing to meet final specs. Then, subassemblies and function tests confirm fit and performance. Furthermore, cleaning removes coolant and chips before packing. Each finishing step improves durability, corrosion resistance, and appearance. Therefore, thoughtful post-processing readies components for demanding applications and guarantees the performance of CNC machining parts.

Packaging, traceability, and delivery of CNC machining parts

Prepare parts for shipment and installation. Clean and protect components, then pack them to prevent transit damage. Add labels, batch numbers, and inspection reports. Also, include material certificates and compliance documents when required. Maintain traceability so any issue can be traced back to the process data. Then, choose reliable carriers and confirm delivery schedules. In doing so, you preserve quality from factory to field. Ultimately, thoughtful packaging and traceability complete the lifecycle of CNC machining parts.