The post Progressive Dies Design Strategies to Reduce Cycle Time and Boost Yield appeared first on Chaoyang.

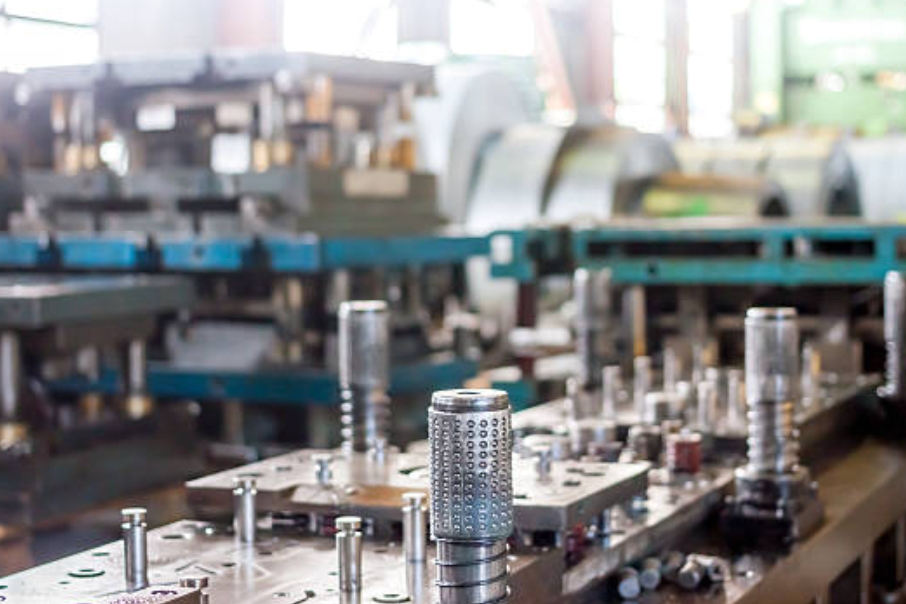

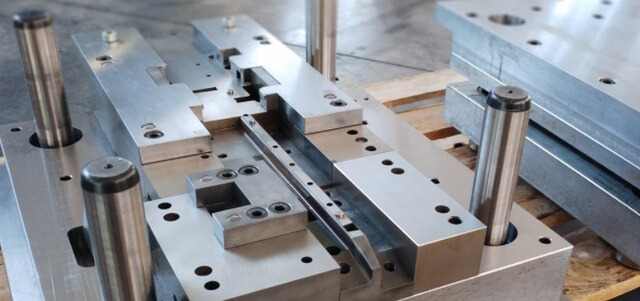

]]>Optimising Strip Layout for Efficiency

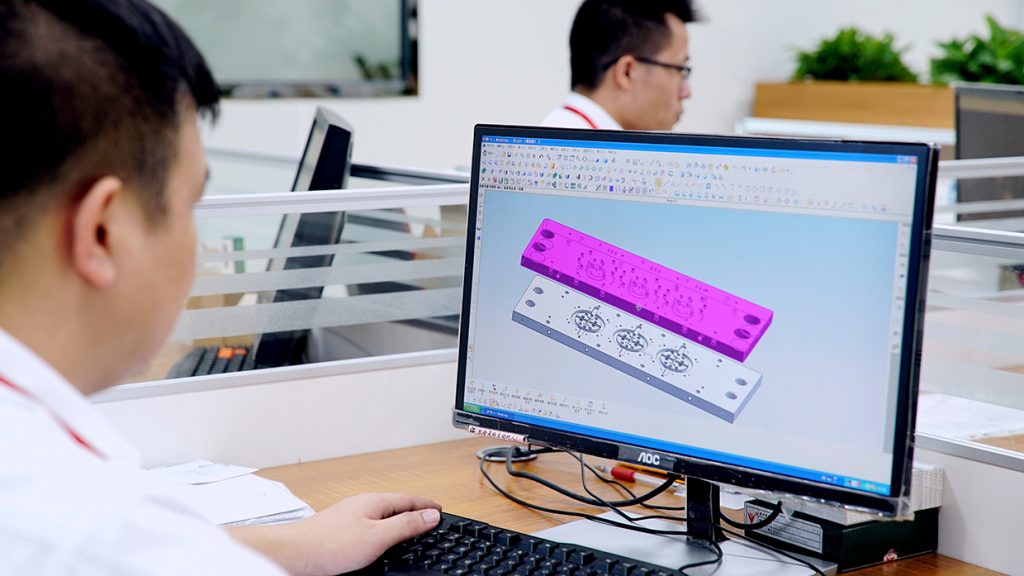

A well-planned strip layout is one of the most effective ways to minimise waste and reduce cycle times. By aligning parts tightly and minimising scrap bridges, manufacturers can cut raw material usage by up to 15% according to a study by the Precision Metalforming Association. Additionally, shorter feed lengths allow presses to run faster without sacrificing accuracy. Engineers should utilise CAD/CAM tools to simulate layouts and identify potential overlaps before conducting physical trials. This reduces the time spent on trial runs and accelerates the launch of new tools, thereby enhancing the performance of progressive dies.

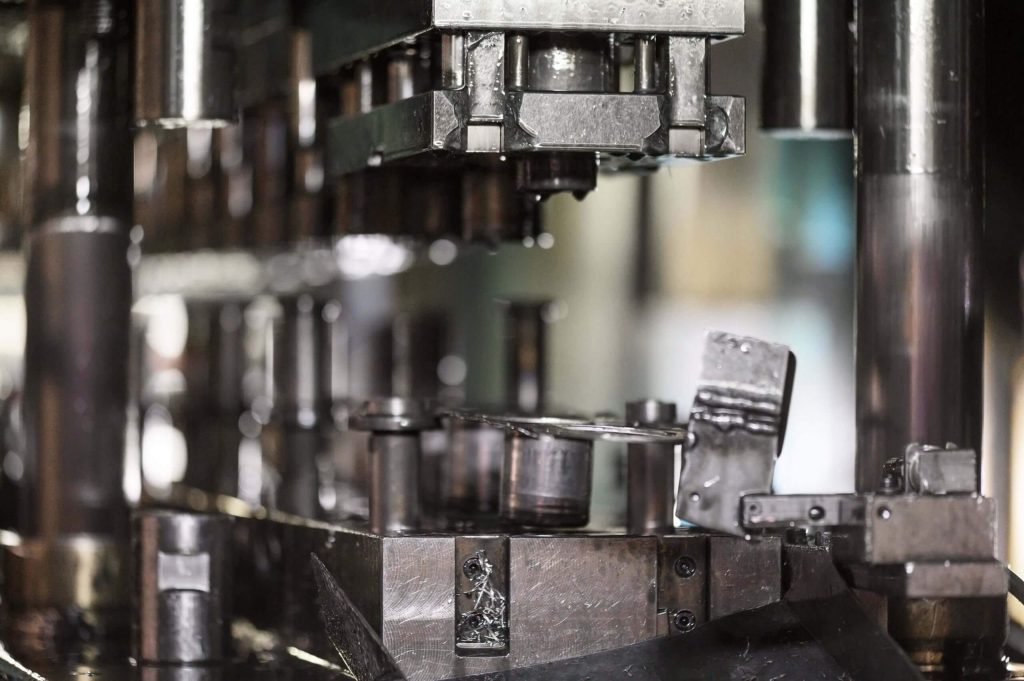

Balancing Tool Stations for Smooth Flow

Each station in the progressive die adds a step to the final product. If the balance is poor, cycle times increase. By redistributing cutting and bending operations evenly across stations, the press force remains stable and vibrations are reduced. Data from the Society of Manufacturing Engineers (SME) indicate that balanced tooling can reduce unplanned downtime by 20%. Moreover, smoother part flow reduces stress concentrations, which minimises premature wear and extends tool life. This strategy ensures that production targets are met consistently, even at higher speeds.

Material Choice and Lubrication Control

Cycle efficiency depends heavily on how the material interacts with the tooling. High-strength steels and aluminium alloys require better lubrication to avoid galling and breakage. According to an Auto/Steel Partnership report, lubrication optimisation can reduce tool wear costs by 12% annually. Progressive dies that integrate lubrication systems at key points minimise friction and heat buildup, allowing presses to run faster and longer. Manufacturers should evaluate different coatings, such as TiCN or DLC, which further improve tool durability under high-cycle conditions.

Precision in Die Clearance and Alignment

Tight die clearance and accurate alignment have a direct impact on part quality and press speed. Misalignment causes burrs, scrap, and press overload. Using laser alignment systems and precision-ground die components ensures that clearances stay within tolerance, even under high production volumes. Case studies from automotive suppliers show that adopting in-die sensors to monitor alignment improved first-pass yield by 8%. This kind of digital monitoring reduces rework and waste, while also extending maintenance intervals for progressive dies.

Incorporating Sensors and Smart Automation

Smart factories are increasingly relying on sensors embedded in their tooling. Load monitors, strip detectors, and part-out sensors can detect problems in milliseconds. When integrated into progressive dies, these devices prevent catastrophic press crashes and reduce scrap. A 2023 Deloitte survey showed that manufacturers using innovative tooling reported an average 17% increase in throughput. Additionally, IoT-enabled sensors provide real-time data for predictive maintenance, minimising unexpected downtime and increasing the effective lifespan of the dies.

Heat Treatment and Surface Enhancements

Even the best-designed dies fail prematurely without proper heat treatment. Applying vacuum heat treatment ensures uniform hardness, reducing the risk of distortion. Surface enhancements, such as nitriding or PVD coatings, extend wear resistance in high-cycle applications. According to research by ASM International, applying proper surface treatments can double tool life in demanding operations. For progressive dies, this means fewer tool changes, less downtime, and higher yield over the lifetime of production programs.

Case Study for Automotive Stamping Success

A Tier-1 automotive supplier implemented optimised strip layouts, balanced station loads, and in-die sensors across its progressive dies. The result was a 22% reduction in cycle time and a 10% boost in yield within six months. Maintenance frequency also decreased, resulting in annual savings of over $500,000 for the company in tooling and labour costs. This example illustrates how design improvements and digital integration yield not only technical benefits but also measurable financial advantages. It reinforces why manufacturers should treat progressive die optimisation as a continuous improvement process, not a one-time task.

Continuous Improvement in Progressive Dies

Reducing cycle time and boosting yield is not achieved through a single tactic, but rather through an integrated approach. From strip layout design to heat treatment and smart sensors, every decision compounds results. Data from across the industry proves that well-optimised progressive dies deliver faster production, higher quality, and lower costs. Manufacturers that adopt these strategies now will be better positioned for the challenges of 2025 and beyond.

The post Progressive Dies Design Strategies to Reduce Cycle Time and Boost Yield appeared first on Chaoyang.

]]>The post Stamping Dies Market Trends 2025 and How Manufacturers Are Responding appeared first on Chaoyang.

]]>Automotive Electrification Driving Die Demand

Electric vehicles reshape tooling requirements. EV battery housings, connectors, and lightweight structures require advanced stamping dies. According to MarketsandMarkets, the global EV market will reach $906 billion by 2028, growing at a 22% CAGR. This expansion increases demand for dies capable of handling aluminium and high-strength steels. Automakers like Tesla and BYD already push suppliers to deliver dies with higher durability and accuracy. These requirements are transforming the design and deployment of stamping dies.

Lightweight Materials and Design Innovation

Manufacturers adopt lightweight alloys to improve fuel efficiency and meet CO? targets. Stamping dies must now be able to handle aluminium, magnesium, and advanced high-strength steels (AHSS). However, these materials increase tool wear and require specialised coatings. According to the International Energy Agency, 70% of automakers plan to integrate more lightweight alloys by 2025. Die makers respond with optimised heat treatments and hybrid die concepts to extend tool life. The shift in material preferences directly influences the design of stamping dies.

Automation and Digital Twins

Automation reduces setup time and boosts throughput. Many factories now use digital twins to simulate die performance before cutting steel. Deloitte reports that 75% of manufacturers with digital twin adoption saw a 20% reduction in downtime (link). In stamping die applications, this means faster validation and fewer trial runs. Robotic integration further improves press efficiency, while predictive maintenance software extends die life. These innovative manufacturing practices are now essential for producing stamping dies.

Regional Shifts and Supply Chain Adjustments

The stamping die market is shifting geographically. The Asia-Pacific region leads production, but reshoring trends in the U.S. and Europe are altering global supply chains. According to Grand View Research, the Asia-Pacific region held 45% of the die demand in 2023; however, North American growth is accelerating due to reshoring policies. Manufacturers respond by building local die facilities closer to OEMs. This reduces logistics costs, supports faster iterations, and stabilises supply chains. The regional transition puts new pressures on stamping dies.

Sustainability and Energy Efficiency

Environmental regulations are now major drivers in the manufacturing sector. Energy-efficient stamping processes cut costs and align with corporate ESG goals. For example, Schuler Group reports that servo presses reduce energy use by up to 30% compared to mechanical presses. Additionally, coating technologies reduce the need for lubrication, thereby lowering the environmental impact. As OEMs adopt stricter sustainability metrics, stamping dies must adapt to more environmentally friendly production methods.

Customisation and Shorter Product Cycles

Consumer demand for faster product updates forces manufacturers to shorten die development cycles. In the consumer electronics industry, new smartphone and laptop models are launched annually. This requires stamping dies to be flexible and quickly retooled. PwC’s survey shows that 60% of manufacturers prioritise agile tooling capabilities to remain competitive. Modular die designs and precision inserts allow faster changeovers. This level of flexibility ensures stamping dies stay relevant in fast-paced markets.

Investment in Skilled Workforce

As automation advances, skilled engineers remain vital for the innovation of stamping dies. Toolmakers must combine traditional craftsmanship with digital tools to achieve optimal results. The U.S. Bureau of Labour Statistics notes a 3% annual increase in demand for tool and die makers through 2032. Companies invest in training to close skills gaps, especially in CNC machining, CAD/CAM, and heat treatment expertise. This human factor remains a core strength in stamping dies development.

Stamping Dies Market Trends 2025

By 2025, the stamping die will be shaped by electrification, lightweight materials, digital tools, and sustainability. Verified data shows rising demand for durable, flexible, and eco-efficient dies. Manufacturers who adapt through automation, local production, and workforce investment will thrive. The future belongs to those aligning the technology with market forces. Ultimately, stamping dies remain at the heart of industrial progress.

The post Stamping Dies Market Trends 2025 and How Manufacturers Are Responding appeared first on Chaoyang.

]]>The post Precision Dies Material Selection and Heat Treatment Guide for Longer Tool Life appeared first on Chaoyang.

]]>Match the steel family to the loading and wear modes

First, identify the dominant load. Does the die cut, blank, form, or stamp at high temperature? For heavy wear and abrasion, high-carbon, high-chromium cold-work steels, such as D2, are commonly used. For hot-forming or die-casting tooling, hot-work steels such as H13 are the most suitable. Tools prone to impact and shock, shock-resistant grades like S7 provide toughness. Match the steel to the load, as the wrong family can deliver poor life, regardless of heat treatment. Industry datasheets and supplier guides summarise recommended applications for each grade.

Understand the trade-off between hardness and toughness

Hardness improves wear resistance. However, excessive hardness compromises toughness and increases the risk of cracking. For example, D2 can reach a hardness of ~60–62 HRC after hardening, which provides excellent edge retention. Yet, D2 can be brittle if not tempered correctly. Conversely, H13 offers good toughness at 45–52 HRC after tempering, which suits hot-work tools that see thermal cycling. Therefore, balance target hardness with the application: choose a higher hardness for abrasive wear and a moderate hardness for shock or thermal stress.

Heat treatment basics: quench, temper, and dimensional control

Proper heat treatment starts with controlled austenitizing and ends with tempering. Quenching creates hard martensite, while tempering reduces brittleness and stabilizes dimensions. For many tool steels, immediate tempering after quench prevents cracking and converts retained austenite. Additionally, tempering cycles determine the final hardness and retained stress. Always follow the supplier’s heat-treatment curves and incorporate stress-relief steps between rough and finish machining to minimize distortion. Reliable vendor guides provide temperatures and hold times for common grades.

Surface engineering nitriding, carburising, and coating

Surface treatments give a hard skin while preserving a more rigid core. Nitriding forms a hard nitride layer at lower temperatures. It enhances wear and fatigue resistance without significant core changes, making it ideal for tooling that requires a thin, hard surface. In contrast, carburizing produces a deeper, carbon-enriched case for parts that require a thick, rigid surface layer. For many die applications, thin, hard coatings applied by PVD, such as TiAlN, significantly reduce abrasive wear and extend intervals between regrinds. Combine surface treatments with base alloy choice for best results.

Use shot peening and residual-compression methods to fight fatigue

Fatigue often kills at corners and holes. Shot peening induces compressive residual stresses in the surface, which delays crack initiation. Additionally, proprietary surface modifications can significantly mitigate stress-corrosion cracking and dramatically extend the life of components in corrosive or cyclic load environments. For stamping and high-cycle tools, shot peening, combined with appropriate heat treatment, has shown measurable life gains. Therefore, include peening in the arsenal, especially where cyclic fatigue limits the life of components.

Cryogenic processing and PM steels

Cryogenic treatment aims to transform retained austenite to martensite and refine carbide distribution. Studies have reported improved wear resistance and stability after deep cryogenic cycles, particularly in tool steels that are subject to abrasive wear. Meanwhile, powder-metallurgy (PM) tool steels offer uniform carbide distribution and superior toughness. PM grades often outperform conventional cast/forged steels in life-critical dies. Thus, consider cryo-treatment for existing dies and PM steels when designing new high-performance tools.

Practical process controls to minimise distortion and rework

Control matters. Preheat uniformly before hardening and cool with consistent quench media to avoid cracking. Machine with recommended allowances; perform intermediate stress-relief cycles before finishing machining. Additionally, measure and log the dimensional change after heat treatment to refine machining allowances. Use statistical process control for heat-treat batches. These practical steps minimize surprises and reduce costly rework. Supplier tech notes explain typical dimensional changes and recommended machining allowances for specific steels.

Design, surface finish, and maintenance checklist for Precision dies

Design for longevity. Use radii at stress points, avoid sharp internal corners, and specify fillets that reduce local stress. Then, select a steel that matches the wear and shock requirements, and define a heat-treatment recipe that balances hardness and toughness. Next, add a surface treatment, such as nitriding, carburizing, PVD coating, or shot peening, as required. Finally, document inspection intervals, regrind limits, and remanufacture plans should be established. Doing this makes Precision dies last longer, reduces downtime, and cuts total tool cost. For authoritative guidelines, consult supplier heat-treatment datasheets and peer-reviewed studies when specifying materials and processes.

The post Precision Dies Material Selection and Heat Treatment Guide for Longer Tool Life appeared first on Chaoyang.

]]>The post Precision Jigs Best Practices to Cut Setup Time and Improve Production Throughput appeared first on Chaoyang.

]]>Start with process mapping and SMED principles

First, map out your current setup step by step. Then, separate the internal from the external steps. In other words, move as many tasks as possible off-press or off-machine. This is the core of SMED (Single-Minute Exchange of Die). In practice, SMED helps teams find hidden waste and convert tasks into external work. When shops apply SMED rigorously, they often significantly reduce changeover time. For background and method, see SMED resources and case guidance.

Design jigs for repeatability and quick location

The precision jig must automatically locate parts. Therefore, use kinematic locating points and hardened datum surfaces. Next, design clamps that lock with one motion. Also, use poka-yoke features to prevent incorrect placement. As a result, operators spend far less time measuring or adjusting. Moreover, a consistent location reduces part variation and scrap. Good jig design is the fastest route to repeatable first-offs.

Adopt quick-change hardware and standard interfaces

Standardise interfaces across dies and fixtures. For example, apply a uniform clamping plate or quick-lock pin system so dies mate instantly. In effect, a standard interface removes alignment guesswork. Additionally, utilise quick-disconnect utilities for air, coolant, and sensors. That way, teams can convert internal steps to external ones, thereby speeding up the changeover process. Industry examples demonstrate that quick-change systems can reduce die setup time from hours to minutes.

Use modular, adjustable jigs to handle families of parts

Instead of building one-off fixtures, design modular jigs. Use interchangeable sub-fixtures, adjustable stops, and indexed mounting patterns. Consequently, you reduce the number of complete changeovers when switching similar parts. Additionally, modularity reduces tooling costs and storage space requirements. Therefore, manufacturers achieve both flexibility and consistency with fewer bespoke fixtures.

Integrate sensors, visual cues, and SOPs for standard work

Combine physical jig design with clear standard work. For example, add visual alignment marks and torque-limited fasteners. Also, include sensors that confirm correct clamp engagement. Then, link these signals to a visual board or PLC to confirm readiness. This integrated approach prevents missed steps and speeds operator confidence. Importantly, standard work makes changeovers predictable and repeatable across different operators.

Train teams and run focused SMED events

Training matters. Run focused SMED workshops with cross-functional teams. During the event, take each step, test alternative methods, and document the new sequence. In many cases, firms reduce setup times by 30–50% after a single SMED cycle. Furthermore, continuous kaizen efforts following the event capture incremental gains. For real-world evidence and structured steps, SMED case studies and academic papers provide tested templates.

Leverage mechanical aids, motion control, and die handling

Don’t rely solely on human muscle. Use hoists, pre-rollers, and guided trolleys to position heavy dies. Moreover, implement motorised motion control for fine alignment where appropriate. In several press-floor case studies, motion control and guided handling reduced die change time from approximately two hours to ten minutes. Consequently, mechanical aids not only speed changeovers but also improve safety and reduce damage risk.

Action checklist and why Precision jigs matter

Finally, act with a practical checklist. First, map your current changeover and apply SMED to separate external tasks. Second, standardise interfaces and adopt quick-change hardware. Third, design jigs with kinematic locators, single-motion clamps, and poka-yoke features to ensure accuracy and prevent errors. Fourth, choose modular elements to handle part families. Fifth, add sensors and visual cues tied to SOPs. Sixth, run SMED workshops and train operators. Seventh, invest in mechanical handling and motion control for heavy tooling. Together, these steps cut setup time, improve first-pass yield, and lift throughput. In short, well-engineered Precision jigs transform changeovers from a bottleneck into a competitive advantage.

The post Precision Jigs Best Practices to Cut Setup Time and Improve Production Throughput appeared first on Chaoyang.

]]>The post How CNC Machining Parts Are Powering EV and Aerospace Component Innovation? appeared first on Chaoyang.

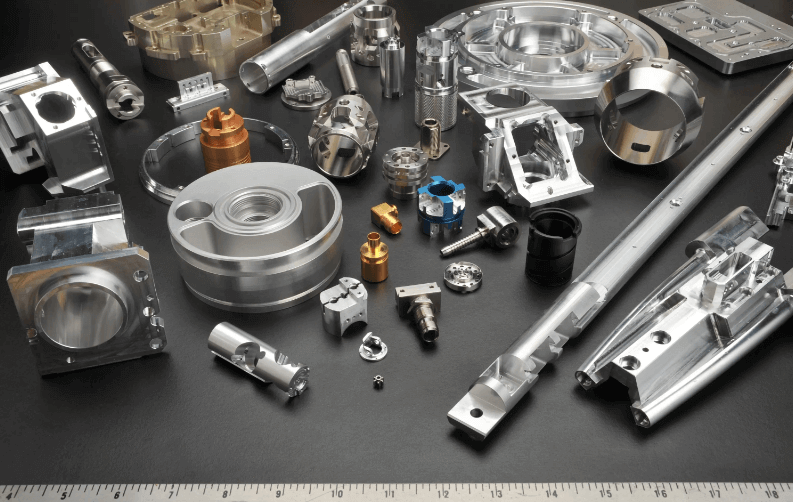

]]>Precision and tolerances that meet strict requirements

Modern aircraft and EV systems need parts machined to micron-level precision. CNC mills and multi-axis turning cells achieve tolerances that hand methods cannot match. As a result, engineers hit performance targets for bearings, housings, and structural brackets. For example, aerospace work routinely specifies tolerances of ±0.001 inch for critical components, which CNC shops consistently deliver. Consequently, designers rely on CNC machining to meet certification and safety margins.

Advanced materials machining for strength and weight savings

Lightweight alloys drive both industries. Aerospace uses titanium and Inconel for strength at low weight. EV manufacturers use aluminum and high-strength steels to cut vehicle mass. CNC machines handle these alloys with the proper tooling and process control. Moreover, research indicates that machining surface integrity is crucial for fatigue life in titanium and nickel alloys. Therefore, controlled CNC processes produce parts that meet fatigue and thermal requirements in engines and battery systems.

Rapid prototyping shortens design cycles

Product teams iterate quickly by moving from CAD to machined prototypes in days, not weeks. Digital manufacturers such as Protolabs and Xometry specialize in on-demand CNC runs for startups and OEMs. As a result, EV designers can test motor housings, mounts, and brackets early. Likewise, aerospace engineers can validate fit and function before committing to expensive tooling. Consequently, rapid CNC prototyping accelerates time to market and reduces costly late-design changes.

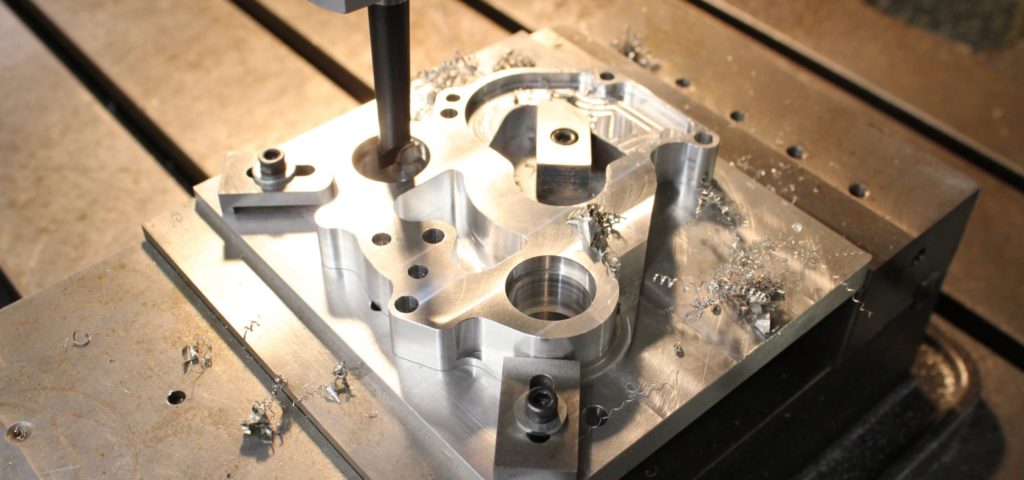

Complex geometries and multi-axis capability enable innovation

Multi-axis CNC enables teams to produce features that previously required assembly. Engineers can machine complex cooling channels, tight internal pockets, and curved surfaces in a single setup. Therefore, designers reduce part counts and join operations. In aerospace engines and EV power electronics, fewer joints mean fewer failure points. Additionally, advanced fixturing and CAD/CAM strategies enable the production of these complex parts at scale with repeatability.

Supply chain flexibility and low-volume production

EV startups and tier-one aerospace suppliers both need flexible suppliers. CNC shops provide short runs and fast turnarounds compared with hard-tooling methods. Consequently, firms scale production in a staged way—prototype, pilot, then ramp. Moreover, digital manufacturing platforms aggregate capacity, providing designers with access to global CNC capacity without the need for lengthy vendor searches. This flexibility reduces inventory risk and supports iterative design choices.

Quality control, inspection, and certification readiness

Aerospace and EV parts require traceable quality data. CNC providers integrate inline inspection, first-article reports, and coordinate measuring machine (CMM) validation. Therefore, suppliers deliver documented conformity for audits. In aerospace, documented process control supports FAA or EASA qualification steps. In EV powertrains and battery modules, consistent dimensional data reduces assembly variance and improves yield. As a result, CNC machining shops act as partners in certification, not merely vendors.

Real-world case studies showing measurable impact

Digital manufacturers highlight concrete wins. For example, a micromobility EV maker sourced half its parts through an on-demand CNC partner and sped production significantly. Similarly, aerospace parts machined from titanium and nickel alloys exhibit high surface integrity and reduced lead times, as reported in published case studies. These examples show how CNC machining delivers both performance and practical business benefits—faster launches, better assemblies, and predictable supply.

Actionable deployment tips for CNC machining parts

Start by defining your critical tolerances and materials. Then, choose suppliers with relevant alloy experience and multi-axis capacity. Next, run small prototype batches to validate fit and function. Also, require documented inspection plans and material traceability. Moreover, consider hybrid workflows—utilizing CNC for critical features and additive methods for complex cores—to optimize both cost and performance. Finally, plan supply continuity by using digital manufacturing platforms or multiple qualified shops. Following these steps lets you use CNC machining part approaches to accelerate innovation, control risk, and scale production reliably.

The post How CNC Machining Parts Are Powering EV and Aerospace Component Innovation? appeared first on Chaoyang.

]]>The post Steps in stamping die design appeared first on Chaoyang.

]]>Part evaluation and DFM kickoff

First, review the part drawing and intended function. Check dimensions, tolerances, and critical features. Next, perform a Design for Manufacturing (DFM) analysis. Identify potential forming issues, such as cracks, wrinkles, or springback. For example, thin metal connectors and IC lead frames require special attention. Also, choose the right material early—stainless, copper alloys, high-carbon steel, or special alloys all behave differently. At this stage, use CAD and CAE tools to run initial simulations. Consequently, you can flag design changes before tooling starts. This early collaboration between design and manufacturing prevents costly rework later.

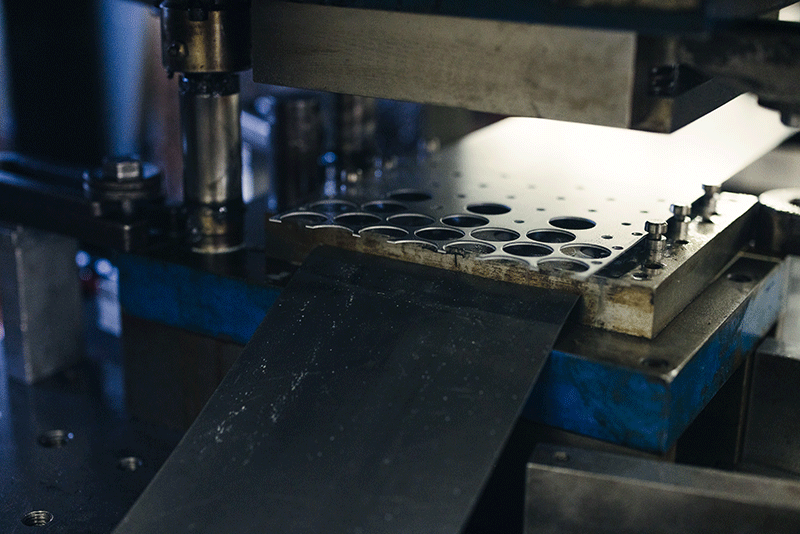

Process selection and material planning

Decide whether to use progressive stamping, transfer dies, or single-station tooling. Progressive dies are suitable for high-volume parts that require a combination of blanking, punching, and bending. Transfer dies work well for deep drawing or complex assemblies. Then plan material flow. Determine coil width, yield strength, and strip layout. Also, check scrap management and blank nesting options. Moreover, choose surface treatments and coatings now—TiCN or DLC coatings increase punch life for hard materials. Proper process selection and material planning set the foundation for a robust stamping die design.

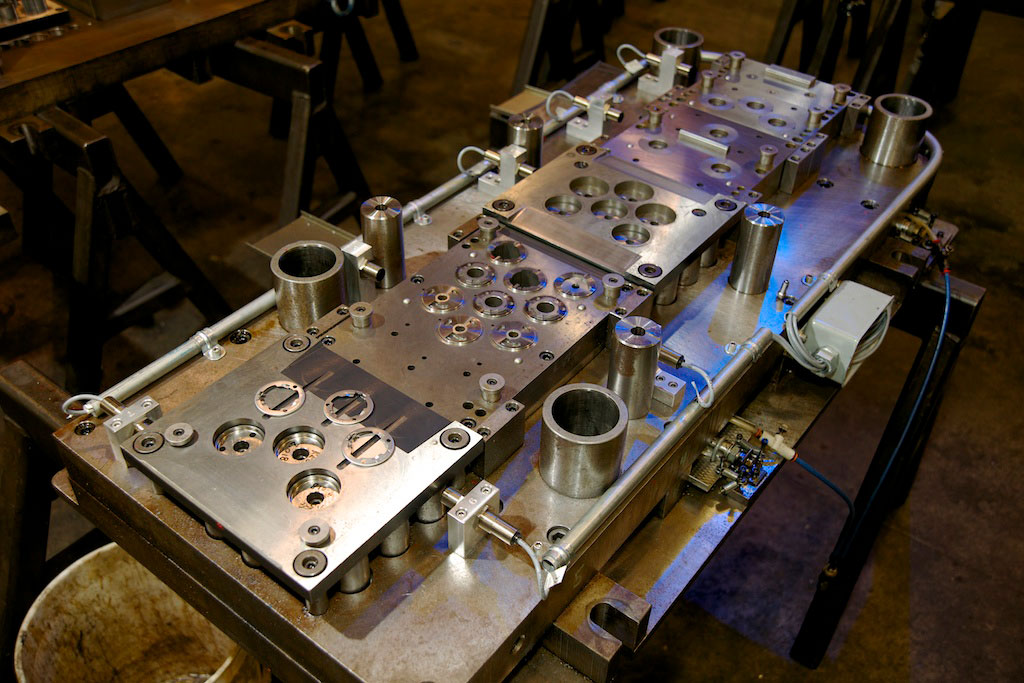

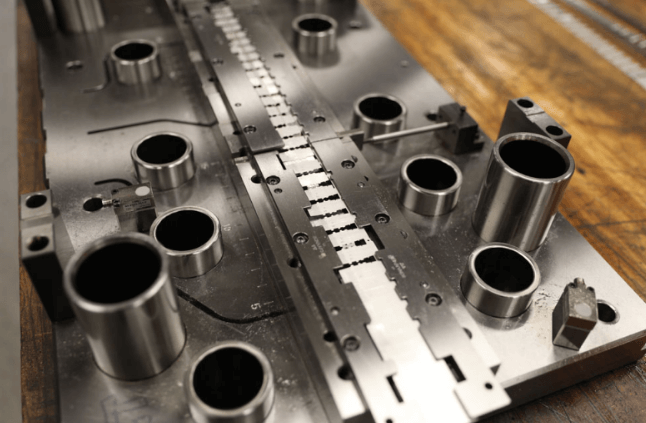

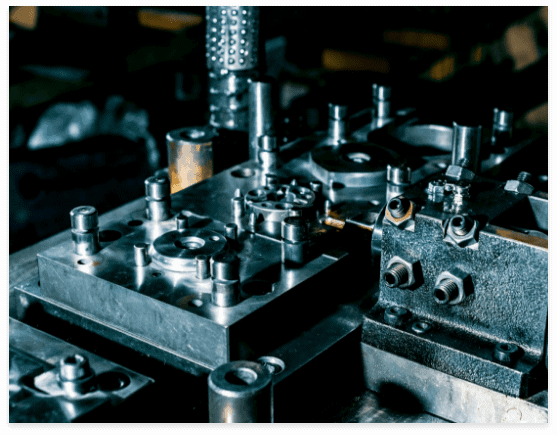

Detailed die layout and stage definition

Now, develop the die layout. Break the process into stages: blanking, piercing, bending, trimming, and forming. Arrange stages to minimize strip travel and reduce waste. For progressive dies, map each cut and form to a specific station and ensure that the strip advance matches the press increments. Meanwhile, define strip guides, pilots, and strip lifters. Also, design the die block, punch sets, and die inserts for easy maintenance. Use 3D CAD to visualize assemblies and to verify clearances. Clear stage definition simplifies maintenance and improves on-press uptime.

Precision tooling and component specification

Specify punches, dies, bushings, and guide systems. Choose tolerances for critical tooling features—punch-to-die clearance often dictates part quality. Also select heat treatment and hardening methods for wear resistance. Where micron-level tolerances are crucial, utilize wire EDM and precision grinding to produce tool components with tolerances of ±1μm as required—furthermore, design for coating application or mirror polishing to enhance part finish and tool life. Additionally, define fasteners and locating features to enable quick replacement or regrinding of components. These specifications make the stamping die design reliable under high-speed production.

Prototyping and soft tooling for validation

Before complete complex tooling, produce prototypes using soft tools or pre-hardened steel. Rapid prototyping helps confirm formability and ensure a proper assembly fit. Run short press trials to collect data on burrs, springback, and dimensional stability. Then, use the results to refine the die geometry and tool clearances. Additionally, perform sample plating or coating tests if the final surface finish is critical to the application. By iterating with soft tooling, you reduce the risk of significant changes after investing in complex tooling. Therefore, prototyping shortens overall time-to-market and improves final part quality.

Die testing, on-press debugging, and metrology

Schedule in-house die testing using production-equivalent presses. During trials, tune tonnage, feed speed, and lubrication. Monitor part consistency across cycles. Utilize advanced metrology tools, including CMMs, optical comparators, and surface roughness testers, to verify tolerances. Record tool wear patterns and check alignment. Also, prepare maintenance and regrind plans based on projected tool life. Provide detailed process documentation so operators follow validated settings. Rigorous testing and measurement ensure the stamping die design will achieve repeatable, zero-defect production.

Industry-specific adaptations and lifecycle planning

Tailor dies to industry needs. For the automotive industry, meet IATF 16949 standards for contact parts, such as battery contacts or sensor housings. For the aerospace industry, follow AS9100 and NADCAP guidelines for lightweight alloys. For electronics and 5G components, focus on micro-features and EMI shielding criteria. Additionally, plan for lifetime support, including maintenance, regrinding, recoating, and component replacement. Offer scalability to increase output without redesign. By aligning stamping die design with sector standards and lifecycle plans, you ensure compliance and long-term cost efficiency.

Production Validation and Improvement

Finally, validate the whole process under production conditions. Confirm that cycle times, scrap rates, and part tolerances meet targets. Provide detailed performance reports. Then, implement continuous improvement by reducing cycle time, extending tool life, and lowering the cost per part. Use feedback loops from production to update CAD models, revise coatings, and optimize press parameters. Additionally, maintain an open line of communication between engineering and production for quick troubleshooting and resolution. By treating stamping die design as an evolving system, you preserve quality and competitiveness over the tool’s life.

Key Takeaways for Stamping Die Design

Disciplined stamping dies design follows a clear, iterative path from DFM and material choice to prototyping, testing, and lifecycle support. Validate each step, then feed production feedback back into the design to reduce costs, minimize scrap, and extend tool life. Use precision tooling, metrology, and proper coatings to ensure repeatable results. Ultimately, a methodical approach transforms a concept into a reliable, high-volume production. Chaoyang has its own in-house design team; if you require die design services, please do not hesitate to contact us.

The post Steps in stamping die design appeared first on Chaoyang.

]]>The post What is the difference between CNC machining and precision machining? appeared first on Chaoyang.

]]>Defining CNC Machining

CNC machining refers to the use of Computer Numerical Control systems to guide machine tools. The process automates cutting, milling, drilling, or turning by programming instructions into the equipment. CNC machines reduce human error and improve production efficiency. Their primary strength lies in repeatability and speed, particularly for large-scale production runs.

Defining Precision Machining

Precision Manufacturing involves producing components with extremely tight tolerances and high accuracy. It does not necessarily mean automation, though CNC is often part of it. The key goal is to achieve exact measurements, smooth finishes, and flawless parts. For example, when creating precision dies used in stamping connectors or Type-C interfaces, manufacturers must maintain tolerances within microns. Industries such as aerospace, medical devices, and electronics depend on Precision Manufacturing to meet strict performance standards.

Core Difference Between CNC and Precision

The primary difference lies in scope and focus. CNC machining is a method of using programmed machines. Precision machining is a goal—the pursuit of exactness and fine detail. While CNC machines can perform precision machining, not all CNC work requires the same level of precision. Similarly, precision machining can be accomplished with CNC or manual methods, as long as the required tolerances are met. In die-making, CNC equipment can cut base shapes, but precision machining ensures the punches and dies align perfectly for repeatable stamping.

Applications of CNC Machining

CNC machining is widely used in industries where consistent production matters. Automotive parts, consumer electronics, and general machinery benefit from the speed and efficiency of CNC machining. It is the go-to process for creating thousands of identical components. For example, CNC milling machines are used to rough-cut large die plates before the finer finishing is handled with Precision Manufacturing. CNC machining shines when accuracy is essential, but not at the highest tolerance levels required in advanced industries.

Applications of Precision Machining

Precision Manufacturing is essential for industries that cannot afford to fail. For example, medical implants must fit the human body perfectly. Aircraft engine parts must withstand extreme conditions with no error. Even minor deviations could cause safety risks. In tooling industries, precision dies used for stamping high-frequency connectors or thin metal sheets require flawless surfaces and ultra-tight tolerances. This makes precision machining indispensable in high-tech and safety-critical fields.

Technology and Equipment Used

CNC machining relies on programmed commands and versatile machine tools such as mills, lathes, or routers. Precision machining, which often utilises CNC equipment, also encompasses techniques such as grinding, electrical discharge machining, and micro-machining. For instance, wire EDM is commonly used in manufacturing precision dies, ensuring sharp corners and smooth profiles that stamping tools demand. These methods allow for extremely tight tolerances and surface finishes that standard CNC cutting cannot consistently achieve. Both approaches benefit from modern software and advanced tooling.

Cost and Efficiency Considerations

CNC machining is generally more cost-effective for mass production. Once programmed, machines can run continuously with minimal oversight. Precision machining, however, often incurs higher costs due to the use of specialised tools, extended setup times, and rigorous quality checks. The trade-off is superior performance and durability of the finished product. A good example is in die-making: CNC can quickly create the overall form, but precision machining ensures the final die can withstand millions of stamping cycles without failure. Businesses must balance budget, volume, and required tolerances when choosing between the two.

Choosing Between CNC and Precision Machining

The difference between CNC machining and Precision Manufacturing comes down to process versus purpose. CNC machining emphasises automation and repeatability, making it an ideal choice for standard production. Precision Manufacturing emphasises accuracy and reliability, serving industries where safety and function are critical. In many cases, companies combine both approaches. CNC machines deliver efficiency, while precision machining ensures perfection. Whether it’s producing complex aerospace parts or manufacturing precision dies for thin sheet stamping, understanding when to apply each process helps businesses optimise performance, cost, and quality. Industries that require the highest standards will always depend on precision machining.

The post What is the difference between CNC machining and precision machining? appeared first on Chaoyang.

]]>The post What steps does CNC machining parts require? appeared first on Chaoyang.

]]>Design and CAD modeling

First, engineers create a CAD model. The model defines geometry, tolerances, and surface finish. Then, designers perform a manufacturability review. They check for thin walls, deep pockets, and undercuts. Next, they add critical dimensions and notes for machining. Importantly, early design for manufacturability saves time and money later. Therefore, good CAD work simplifies CAM programming and reduces errors. In short, the design stage sets the foundation for all downstream work in a CNC machining part.

Material selection and blank preparation

After design, choose the right material. Common choices include aluminum, stainless steel, titanium, and engineering plastics. Material affects strength, weight, and machinability. Moreover, suppliers must provide stable, defect-free stock. Then, technicians cut raw material into blanks sized for the machine. They also inspect for impurities and internal defects. Proper blank preparation prevents vibration and part shift during cutting. Thus, careful material selection and prep directly support dimensional accuracy in CNC machining parts.

CAM programming and toolpath optimization

Next, CAM software converts CAD into G-code. Programmers generate efficient toolpaths and sequence operations. They select speeds, feeds, and tool changes. Then, they simulate the program to catch collisions and errors. Significantly, optimized toolpaths reduce cycle time and tool wear. Also, programmers include coolant strategies and lead-in paths. Consequently, solid CAM work improves quality while lowering cost. In short, careful programming forms the engine that drives accurate CNC machining parts.

Machine setup, tooling, and fixturing

Before cutting, technicians prepare the machine. They install tooling, set offsets, and mount fixtures. Accurate fixturing holds the part firmly and repeats locations across runs. Additionally, they check spindle runout and tool balance. Then, they load the program and run dry cycles if needed. Setup verification ensures the physical setup matches the digital plan. Therefore, a precise setup minimizes rework and scrap. Ultimately, good fixturing and tooling underpin repeatable CNC machining parts.

Machining operations and in-process control

With setup complete, the machine executes the program. Operations include milling, turning, drilling, and tapping. Operators monitor tool wear, chip formation, and machine loads. Moreover, they measure key features during the run when necessary. If a tool shows wear, they change it and adjust offsets. Real-time checks prevent costly failures. In automated cells, sensors can halt the process on anomalies. Hence, active in-process control maintains tolerance and surface finish, which leads to reliable CNC machining parts.

Inspection, metrology, and quality assurance

No parts ship without inspection. Technicians use calipers, micrometers, and CMMs to verify dimensions and geometric tolerances. They also check surface finish and concentricity. First-article inspection validates the setup before complete production runs. Then, statistical process control tracks variation across batches. Nonconformances trigger root-cause analysis and corrective actions. Additionally, traceable records support customer audits and certifications. In effect, rigorous QA systems ensure each batch of CNC machining parts meets the required standard.

Post-processing, finishing, and assembly

After machining, parts often need secondary work. Typical steps include deburring, shot peening, heat treatment, anodizing, and coating. Some parts require precision grinding or honing to meet final specs. Then, subassemblies and function tests confirm fit and performance. Furthermore, cleaning removes coolant and chips before packing. Each finishing step improves durability, corrosion resistance, and appearance. Therefore, thoughtful post-processing readies components for demanding applications and guarantees the performance of CNC machining parts.

Packaging, traceability, and delivery of CNC machining parts

Prepare parts for shipment and installation. Clean and protect components, then pack them to prevent transit damage. Add labels, batch numbers, and inspection reports. Also, include material certificates and compliance documents when required. Maintain traceability so any issue can be traced back to the process data. Then, choose reliable carriers and confirm delivery schedules. In doing so, you preserve quality from factory to field. Ultimately, thoughtful packaging and traceability complete the lifecycle of CNC machining parts.

The post What steps does CNC machining parts require? appeared first on Chaoyang.

]]>The post Chaoyang Precision Machining Services Introduction appeared first on Chaoyang.

]]>Jig Grinding for Ultra-Fine Details

Jig grinding is one of our specialties. It allows us to produce holes, slots, and contours with outstanding precision. We can achieve roundness and processing accuracy as fine as ±0.001mm. This capability is essential for industries where every fraction of a millimeter matters, such as aerospace and medical tooling. Our jig grinders, including Moore machines, ensure consistent results. By maintaining such tight tolerances, we help clients achieve parts that fit and function perfectly. This makes jig grinding a critical part of our precision machining service.

Wire EDM for Complex Shapes

When customers require intricate shapes or excellent features, wire EDM is the solution. Using a thin wire as an electrode, this process cuts through tough metals with ease. We handle a wire diameter range from 0.05 to 0.3mm, achieving surface roughness as low as Ra0.05. This process is especially valuable for dies, punches, and tools that demand precision contours. With equipment from Sodick and Seibu, we offer both oil-based and water-based EDM options. This versatility ensures we can adapt to the specific needs of each project within our precision machining services.

Profile Grinding for Complex Contours

Profile grinding allows us to create intricate geometries that are often impossible with conventional methods. This process ensures tight tolerances and smooth surfaces, which are crucial for stamping dies and advanced tooling. With grinding precision reaching ±0.001mm, we can achieve sharp corners and delicate profiles with ease. It’s not just about accuracy—it’s also about consistency across multiple parts. By delivering reliable results at scale, we strengthen our clients’ production efficiency. Profile grinding is a cornerstone of our precision machining services.

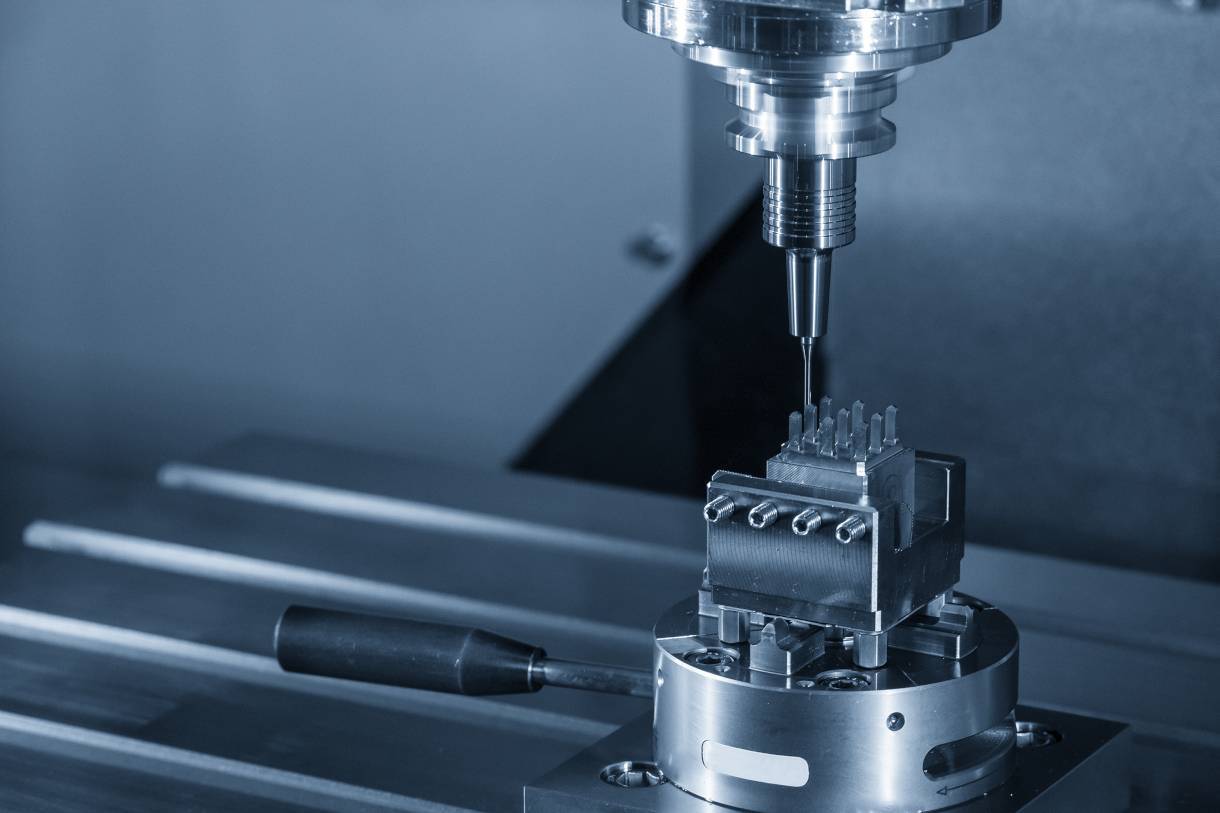

CNC Machining for Versatility

CNC machining provides flexibility for a wide range of parts. Using AWEA, AGMA, and Vision Wild machining centers, we can handle strokes up to 1600x3100mm. These machines allow us to produce parts with complex geometries and repeatable precision. CNC machining supports everything from prototypes to mass production, making it one of the most versatile processes we offer. With computer-controlled accuracy, we ensure every cut is intentional and reliable. This adaptability is why CNC machining remains a vital part of our precision machining services.

Surface Grinding for Perfect Finishes

For components requiring flatness and fine finishes, we offer both large and small surface grinding. Large surface grinding accommodates strokes up to 600x1200mm, while small surface grinding achieves ultra-fine accuracy and minimal roughness. These processes are ideal for hardened steels and critical functional surfaces. Our team ensures each grind meets the highest standards, with roughness values as low as Ra0.02. Surface grinding not only improves part performance but also extends tool life. It remains one of the most essential finishing methods in our precision machining services.

Integration of Advanced Equipment

What sets us apart is the integration of advanced technology in one facility. We combine jig grinding, wire EDM, profile grinding, CNC machining, and surface grinding under one roof. This reduces outsourcing risks, shortens lead times, and ensures consistent quality. Each machine, from WASINO profile grinders to Sodick EDMs, is carefully maintained for peak performance. By keeping all capabilities in-house, we control every step of the process. This seamless integration enhances the value of our precision machining services.

Why Clients Trust Our Expertise

Our clients span industries such as automotive, aerospace, and electronics. They trust us because we consistently deliver precision. With tolerances as tight as ±0.001mm, we support even the most demanding applications. Furthermore, our quality assurance team inspects every component using advanced metrology tools. This ensures compliance with specifications every time. Decades of proven industry experience back our claims, making us a reliable partner for businesses that cannot compromise on quality. This trust underscores the strength of our precision machining services.

Delivering Reliable Precision Machining Services

At the end of the day, precision is about results. Whether you need intricate contours, tight tolerances, or flawless finishes, we have the proper process for you. Our combination of expertise, advanced equipment, and strict quality control sets us apart. From prototype to large-scale production, we adapt to your requirements while ensuring accuracy. For businesses that value consistency and reliability, our precision machining services remain the key to achieving success.

The post Chaoyang Precision Machining Services Introduction appeared first on Chaoyang.

]]>The post How progressive die technology supports electric vehicle production? appeared first on Chaoyang.

]]>Meeting EV Demand with Precision

EV production continues to rise globally, and the supply chain must keep pace. Automakers face pressure to manufacture battery housings, motor cores, and lightweight structural components at scale. Progressive die technology provides consistent part accuracy across thousands of cycles. This repeatability ensures that every component meets tight design tolerances. As a result, EV manufacturers can reduce waste, improve quality, and avoid costly rework through the use of a progressive die.

Efficiency Across Mass Production

EV factories operate under strict timelines. Each second saved per cycle adds up to significant output gains. Progressive dies allow multiple forming steps, such as cutting, bending, and coining, to occur in one continuous press stroke. This integration minimizes downtime between processes. It also reduces manual handling, which improves worker safety. By streamlining production, progressive die enables manufacturers to meet large orders while maintaining consistent product quality.

Lightweight Components for Energy Savings

Lightweight materials directly influence EV performance and driving range. Automakers are increasingly using aluminum and advanced steels in vehicle structures. However, these materials require specialized forming techniques. Progressive die tools are designed to handle high-strength, lightweight alloys without sacrificing precision. The result is durable yet lighter vehicle parts. This supports energy efficiency while also meeting safety standards. Without a progressive die, shaping these materials into consistent parts at scale would be far more difficult.

Supporting Battery and Motor Assembly

The heart of every EV lies in its battery pack and electric motor. These assemblies contain hundreds of stamped components that must fit together with extreme accuracy. Progressive die ensures precision in items such as battery terminals, busbars, and motor laminations. A single defect could reduce performance or cause costly downtime. Therefore, manufacturers depend on progressive dies to achieve reliability in parts that form the backbone of EV power systems.

Reducing Waste in EV Manufacturing

Sustainability is central to EV production, and reducing material waste is a key goal. Progressive dies technology maximizes sheet utilization, leaving minimal scrap after stamping. This efficiency not only lowers raw material costs but also reduces environmental impact. Automakers can improve their sustainability profile while maintaining profitability. Furthermore, less scrap means fewer recycling processes, lowering the total energy footprint. Progressive die supports both economic and ecological goals in EV manufacturing.

Integration with Automation Systems

Modern EV plants are heavily automated. Robots, conveyors, and inspection systems are all connected to ensure efficiency. Progressive dies integrate seamlessly with these systems. Automatic feeding of coil material, in-die sensors, and real-time monitoring improve consistency and reduce downtime. As EV demand continues to expand, this integration allows manufacturers to scale without sacrificing quality. Progressive die, therefore, fits perfectly into the smart factory environments shaping the future of automotive production.

Lower Costs Through Long Tool Life

The EV industry requires competitive pricing to attract more consumers. Reducing production costs is essential. Progressive die tools are built for durability and long service life. With proper maintenance, they can run millions of cycles before requiring replacement. This longevity reduces tooling costs and production interruptions. It also ensures predictable expenses for manufacturers. Lower costs combined with high output help automakers remain competitive in the rapidly growing EV market. Progressive die proves cost-effective over time.

The Role of Progressive Die in EV Production

Electric vehicles are transforming transportation. To keep up, automakers must use technologies that support high output, consistent quality, and sustainability. Progressive die technology delivers on all these fronts. It enables mass production of lightweight, precise, and durable components while keeping costs under control.

The post How progressive die technology supports electric vehicle production? appeared first on Chaoyang.

]]>